Comment | Cheap plastic is flooding developing countries – we’re making new biodegradable materials to help

Squeezed by lower fuel demand during the pandemic and the rise of renewable energy, the oil industry is staking out a new future for itself in plastics. Instead of powering vehicles or generating electricity, oil companies are increasingly looking to use their product to manufacture cheap plastic packaging, which they can sell in lower to middle income countries.

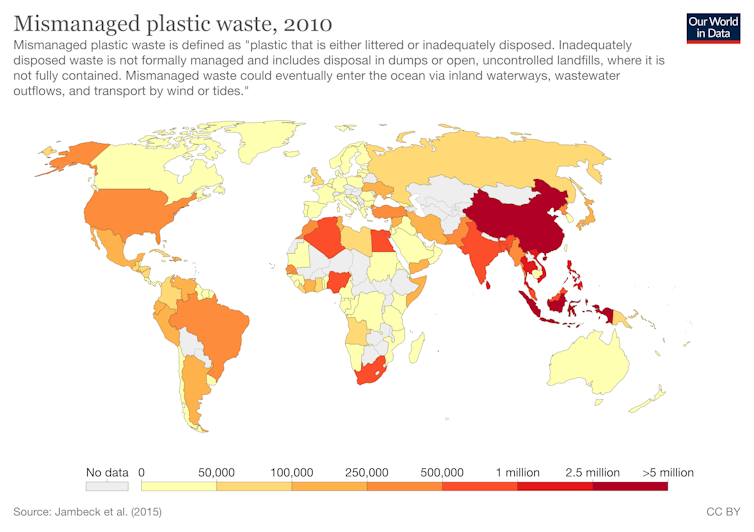

The problem? Many countries lack the means to recycle even their own plastics. Countries in the developing world are already inundated with plastic exported for sorting and reprocessing by higher income nations, so oil companies are effectively threatening to flood the developing world with a new wave of virtually unrecyclable plastics. Companies in the US are setting the groundwork for this right now by lobbying to undermine Kenya’s plastic bag ban.

The vast amounts of plastic waste that have already accumulated in the developing world are not being adequately managed. Landfill and incineration are the most common solutions, but burning plastics releases toxic chemicals. In reprocessing or landfill facilities, plastics often escape to choke rivers and coastal seas. Even lying around on the soil, plastics cause problems. A team of researchers in China found that the number and variety of insects and worms in soil was significantly reduced when LDPE – the kind of plastic carrier bags are made from – was spread over the earth.

As pressure to sell more plastics to the developing world grows, so does the body of evidence demonstrating the harms caused by this waste accumulating in the environment. This calls for locking waste plastics in “safe sinks”, like wood-plastic composites.

Biodegradable composites

Waste plastics from homes and businesses, like used carrier bags, can be collected, cleaned and combined with natural materials such as sawdust. These new composite materials lock plastic debris in a stable form, preventing it from being broken up and scattered into soils and the ocean. New materials could eventually replace plastics derived from petroleum and turn off the tap of new plastics production. But for now, these safe sinks are a vital step.

Our team at Universiti Sumatera Utara (the University of North Sumatra) in Indonesia recently developed a wood-plastic composite for use in construction. Combining LDPE and durian wood sawdust from a local sawmill, we pressed out composite materials suitable for building homes, fencing and furniture. Our study demonstrated that termites native to Indonesia can ingest these composite materials when buried in the soil, but we still need further research.

The termites have LDPE in their guts, but we’re not yet sure if they are digesting the plastics entirely or just breaking them up into micro and nano-plastics. Some termites cultivate microorganisms in their nests which can degrade LDPE plastics. Do ours? If not, introducing new termites or microbes that aren’t indigenous to Sumatra might create even bigger problems.

North Sumatra is home to rainforests, rhinos and tigers, and local ecosystems are vulnerable. People living in remote communities typically want the convenience of consumer goods, processed food, medicines and other amenities that come with plastic packaging. But they don’t want the waste it generates. Most of these communities lack solid waste management services, so burning and burying are their only options. While people on the nearby Indonesian island of Java enjoy a higher standard of living, their rivers are more polluted with plastic than any others in the world.

Our wood-plastic composite could replace wood, plastic decking or fencing, diverting plastic waste from the environment and easing the pressure on forests for building supplies. But we also need to test if our biodegradeable composite is safe. We don’t yet know if it will be more or less of a fire hazard than other building materials available on the Indonesian market. Flammability assessments are important – recycled plastic decking recently caught fire and burned down an ancient archaeological site in Australia.

Global materials research

Durian wood evolved in concert with insect and microbial life in Indonesia that was capable of decomposing it. Combining plastic waste with materials that are part of local ecosystems could ensure that resulting composites are biodegradable within the environments they’re created, wherever that is in the world. Scientists have discovered some aspects of natural systems that can break up and degrade plastics. We used termites and their associated microbes, but moth larvae and plastic-eating bacteria might also work.

Worldwide, sawmills are producing dust and flour from local wood that could be combined with ubiquitous plastic waste. Where emerging markets are likely to be targeted with cheap plastic packaging, scientists could adapt our procedure for making composite materials to local conditions.

These composite materials are promising as safe sinks for plastic waste, but they take time to develop. They’re most useful for countries inundated with plastic waste which lack the capital investment for most technical fixes, and have an even greater problem developing reliable solid waste management infrastructure. Though plastics are a global issue, it is this kind of low-cost, local research that can help solve the plastics crisis where it is felt most acutely.![]()

Deirdre McKay, Reader in Geography and Environmental Politics, Keele University

This article is republished from The Conversation under a Creative Commons license. Read the original article.

Most read

- Keele University partners with Telford College and NHS to teach new Nursing Associate apprenticeship in Shropshire

- Emotion aware chatbot developed by Keele scientists offers transformative potential for mental health care

- First study of its kind sheds new light on Britain’s ‘forgotten’ World War Two decoy sites

- Keele cardiologist travels to Ethiopia to improve care for heart patients

- Keele academic wins prestigious prize for short story set in Stoke-on-Trent

Contact us

Andy Cain,

Media Relations Manager

+44 1782 733857

Abby Swift,

Senior Communications Officer

+44 1782 734925

Adam Blakeman,

Press Officer

+44 7775 033274

Ashleigh Williams,

Senior Internal Communications Officer

Strategic Communications and Brand news@keele.ac.uk.